This guide will help you install a Fungineers motor cable in your Hypercore motor. This method replaces the entire cable, leaving you with a reliable and professional-looking conversion that will last for years. No splicing, no cable bulge, and extra length tucked inside the axle for future length adjustments.

Modifying the internals of a motor can be daunting! Please familiarize yourself with the full process before starting. Nothing worse than getting 3/4 finished and realizing you forgot to order sealant or replacement bearing o rings!

Tools:

- allen keys

- soldering iron

- solder sucker or solder wick

- side cutters

- wire strippers

- flat head screwdriver (to poke the black sealant out of the axle)

- tweezers (to untie and tie the string)

- heat gun

Materials:

- Hypercore

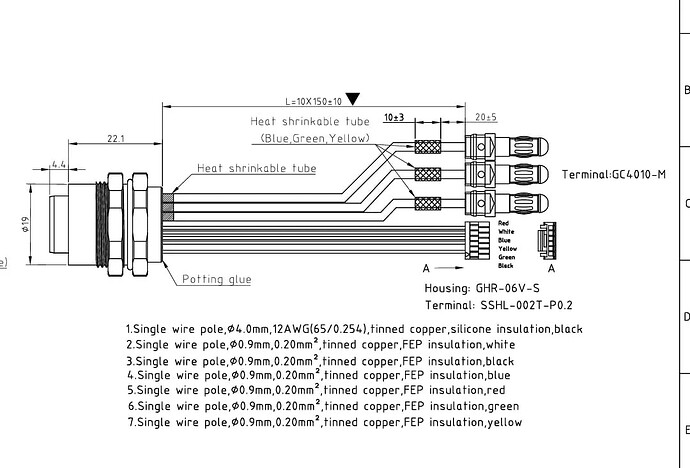

- Fungineers motor connector (motor side)

- solder

- heat shrink

- flowable silicone (or another heat resistant sealant)

- replacement bearing o rings (XR or GT/Pint)

Steps:

-

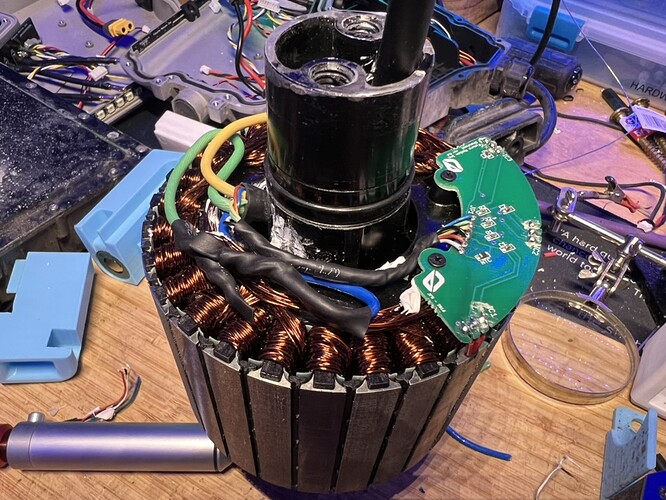

take the stator out of the hub:

- remove the 7 bolts from the cover plate

- bolt a rail onto the axle on the plate side and use it to lift the stator out of the hub

- remove the rail and axle block, then pull the cover plate off

-

disconnect the old motor cable wires:

- untie the string holding down the wires and save it for later

- take the heat shrink off of the phase wires

- desolder and disconnect the phase wires from the windings

- note: if you accidentally cut one of the motor windings, you’ll need to scrape off the nonconductive coating before resoldering the wire back together

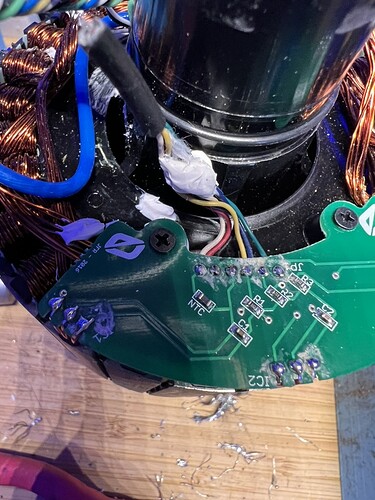

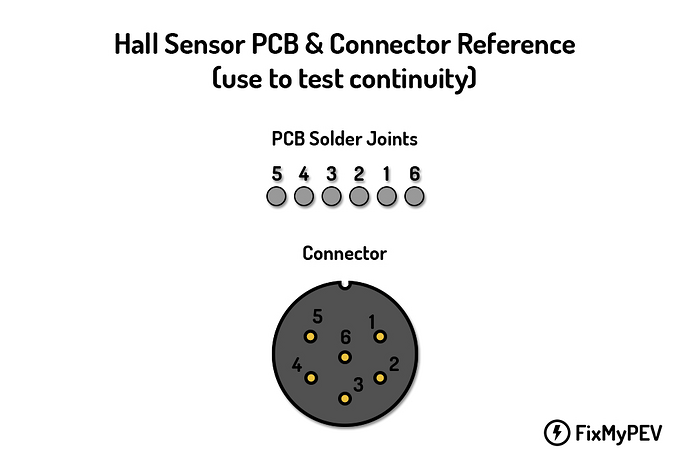

- take a picture of the hall sensor PCB to remember the order of the wires!

- unsolder the small wires (temp + hall sensors)

-

remove the old cable:

- carefully pick away as much of the white sealant from around the phase wires as you can

- pick away as much of the black sealant from inside the axle as you can

- remove the rubber seal from the motor cable side of the axle

- pull the old motor cable out of the axle

-

insert the new cable:

- feed the new motor cable through the rubber axle seal

- feed the cable into the axle and through the cable hole

- fold the excess cable in half and shove it into the axle so you can adjust the cable length later

-

connect the new phase wires:

- cut the phase wires to length and strip them

- solder the phase wires to the motor coils

- cover solder joints with heat shrink

-

connect the hall and temp sensor wires:

- twist the small gauge wires together and cover the bundle with heat shrink

- cut the wires to length and solder them to the PCB in the same color order as before: [ temp ]-[ 5v ]-[ ground ]-[ hall 1 ]-[ hall 2 ]-[ hall 3 ]

-

secure and seal the new cable:

- tie the string back in place to keep the wires away from the rotating cover plate

- use flowable silicone or another heat resistant sealant to waterproof and further hold the wires in place

- [optional for further waterproofing] adjust the length of the motor cable in the axle, then fill both side of the axle with silicone to fully seal the axle

- let the sealant cure overnight

-

reassemble the motor:

- install new o rings on the axle

- slide the cover plate over the new motor connector and press into place

- spin the cover plate to ensure the wires aren’t rubbing

- attach a rail to the plate side of the stator and lower the stator into the hub

- align the bolt holes in the cover, then press the stator firmly down into the hub

- reinstall the cover plate bolts, tightening in a star pattern to apply even pressure around the plate

- reinstall motor into your board and re-run motor wizard