This is a mirrored log article that accompanies the video series I’m working on for my build.

This article will be updated as each part is completed, and I will continue to add into it until the final test ride is done. This write-up will contain affiliate links and non-affiliate links to the parts and products used in my build, and I will update those as well as more parts may be needed with each part of the build.

At the center of this entire project, is The VESC Project:

The principal author of the Balance App code that allows balance vehicles to run on VESC is Mitch Lustig:

One of the most involved, helpful, and brilliant contributors to custom code, which makes the boards ride well, is Dado Mista, respectfully known as surfdado:

Kits, VESCs (Little FOCers) and other items can be found:

https://customwheel.shop/ (Europe)

https://www.makerspev.com/ (U.S.A.)

This write-up will be mirrored, as linked below:

The Start: What Is VESC?

It all starts here, with the first video in the series. Here, I lay out a primer on what VESC is, and explain a bit about ESCs (Electronic Speed Controllers, or motor controllers), what they’re about, and why the Vedder Electronic Speed Controller is an important part of the PEV (Personal Electric Vehicle) community.

*Please keep in mind, that many of the links and pages that you will find in this article, themselves have linked pages with more information for reference. If you are a new builder, then it is in your best interest to just go down the rabbit hole of DIY PEV building. There are many dangerous aspects to it, but learning to build and make things yourself is a rewarding hobby, and is worth learning to do properly.

I tend to now publish media and writings on my projects, not as “how to” guides, but as logs of “what happened” when I went through a project. The knowledge gained for these projects was acquired through countless hours of reading, asking questions, and trying and failing.

Part 1: Going Over Parts

In the next video installment, I explain what parts I will be using.

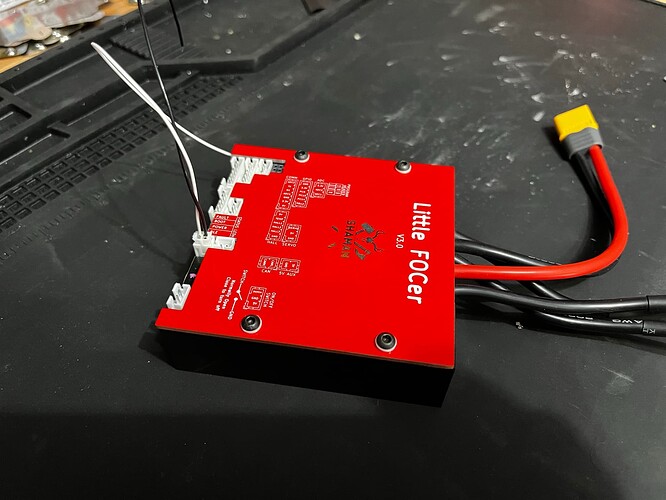

There has been a change since this parts video, and I am no longer using the V1 Little FOCer for the build. I am instead using a V3.1 Little FOCer, and most of the parts from the DIY kit which can be found at:

^Please note that this product page also has refernce links that would be useful.

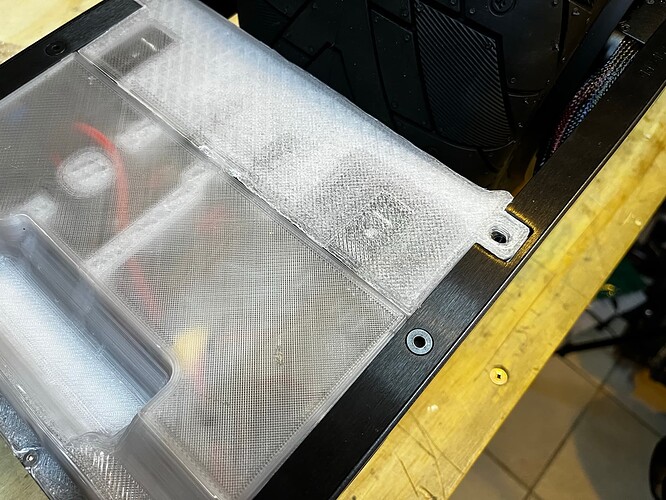

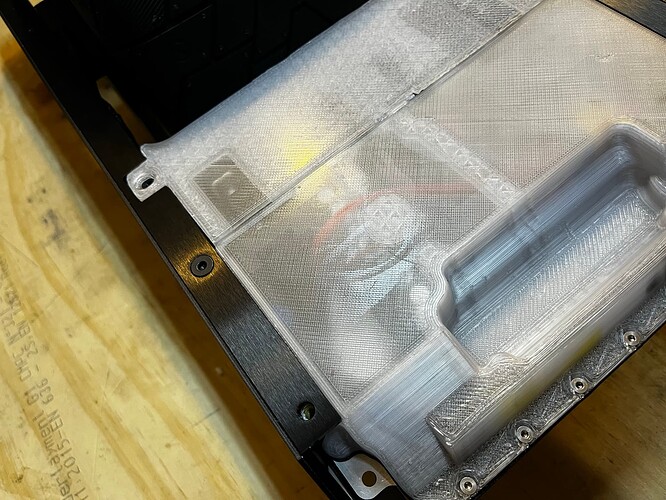

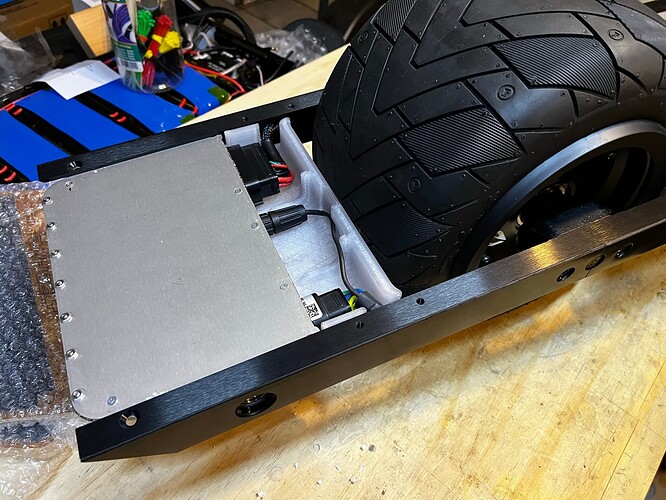

It is because of this change to the V3, that a lot of the tedious rework on the FOCer could be skipped, and the ESC enclosure box being used was no longer the original black Impact PLA print, but a transparent print from MakersPEV.

The rest of shown parts here are still planned to go into the build. Please see the video description for more information.

Part 2: Assembling the Controller (Front) Enclosure Box

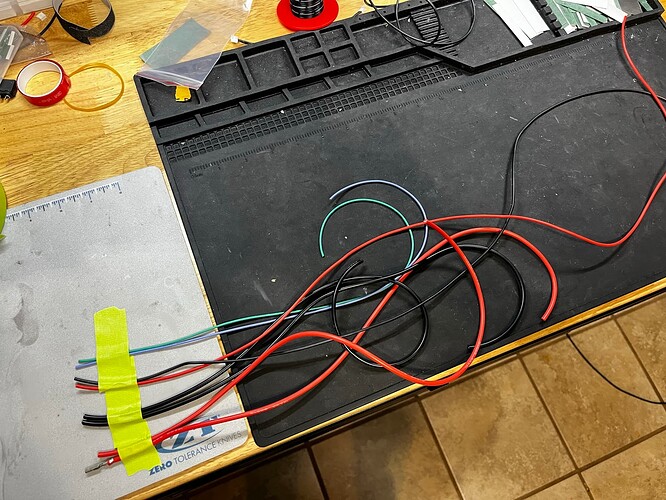

Aside from the above video, there are parts of this assembly that I’d like to mention in more detail with some photos.

As was mentioned, I did indeed change out the motor phase wires. The initial idea was to just angle one so that it would clear the inner support post of the enclosure box, but that proved a bit more difficult than I thought. I HATE lead free solder. Hate it. It melts inconsistently, crystalizes like crazy even near an iron, and makes for poor joint reflowing unless you dump excessive heat into it. And it takes a lot of flux (or more corrosive flux) to keep it pooled properly.

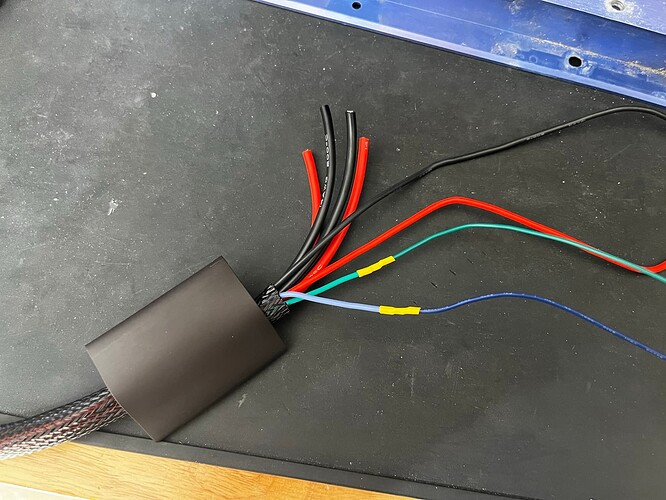

I understand why it’s used, but if I ever get the chance to remove it, I usually do it. So in this case, working with the lead free solder gave me a hard time, I ended up wicking some more solder up the strands of the wire, and it left a 1/4” length of the wire a bit stiffer than I wanted it to be. So, that was my opportunity to just replace the phase wires with longer ones.

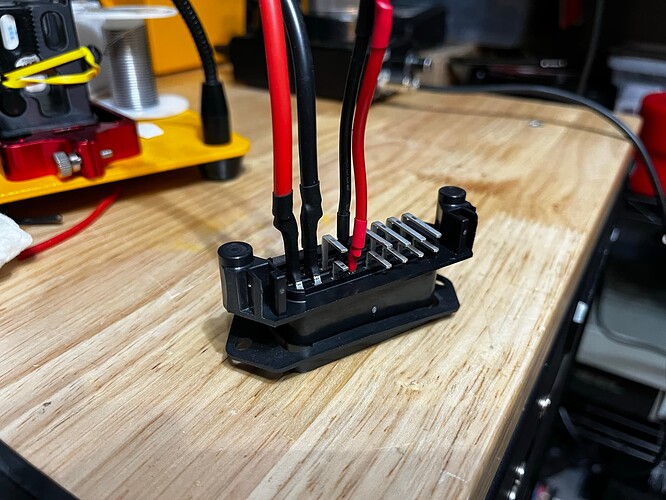

Having done it, I do believe the phase wires should be a bit longer than they were stock, and that’s because the included adapter that goes from 4mm bullet connectors to the 6-pin Molex for the motor, is very short and entirely rigid. I’m sure it could technically fit, but I wasn’t really keen on forcing anything or having extra pull stress on any wiring or connections. So, along with the longer phase wires off the FOCer, I added length to the adapter.

After all that, of course, was more bench testing.

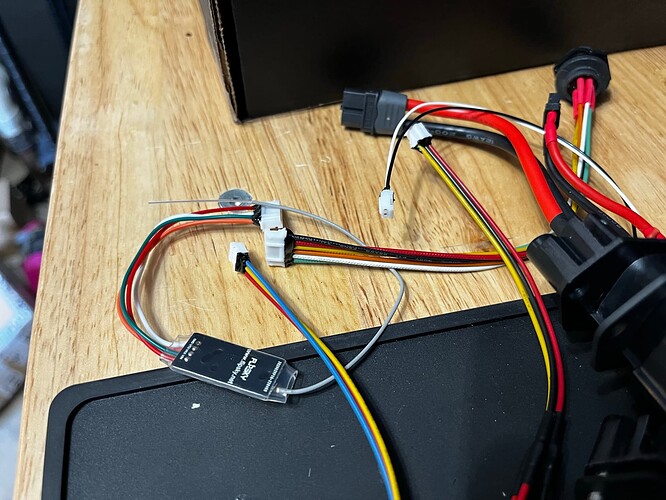

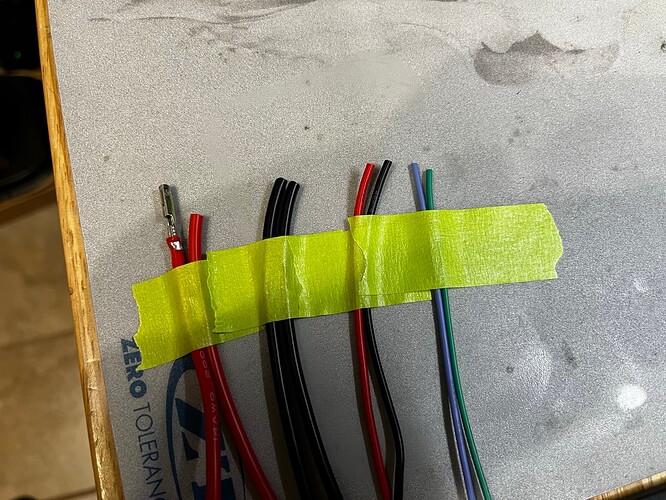

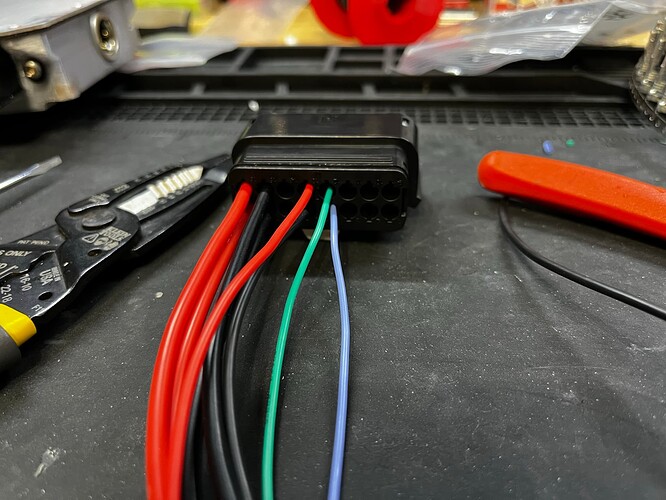

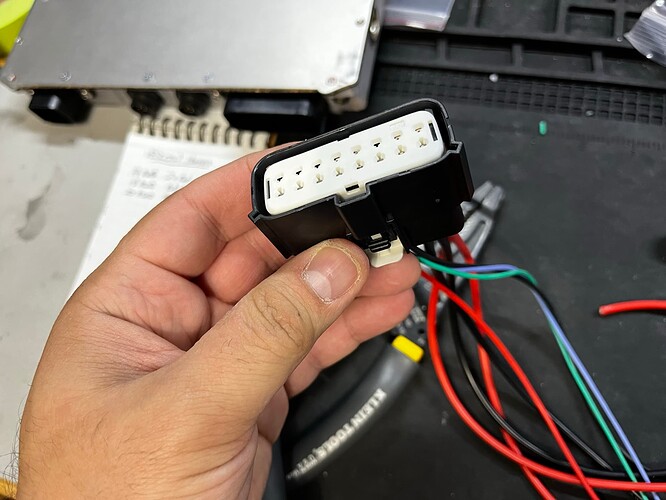

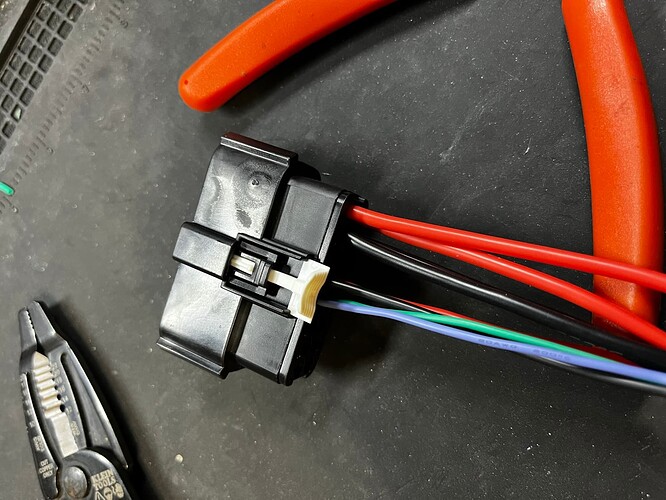

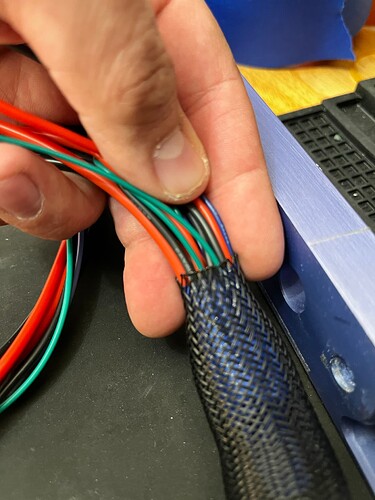

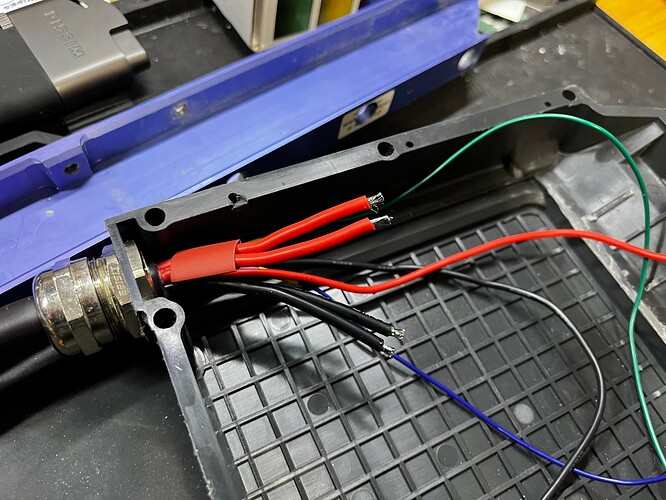

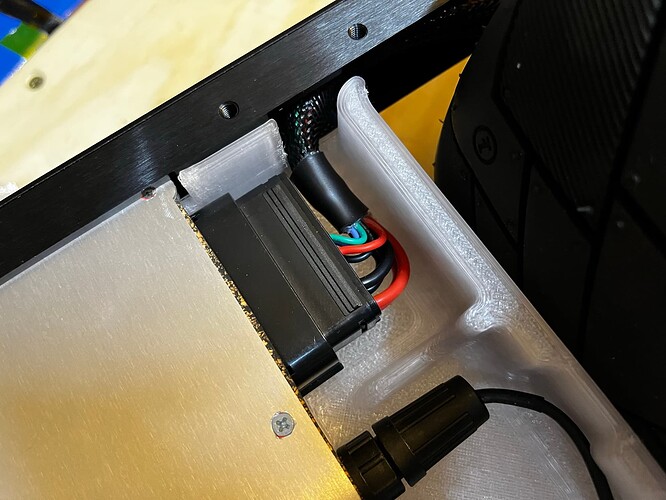

The other modifications to the wiring I did was mostly around the power connector. The stock 16-pin Molex coming from the plug, has the power connection shared between the discharge path and the charge path. This is fine if you are using JUST the retrofit box, and a stock Onewheel battery box, battery, BMS and harness. In THAT case, the power going to the ESC, and the power going into the BMS from the charge port, follow the same path.

IF YOU ARE USING A CHARGE ONLY BMS, such as an ENNOID, or a ZBMS, or something like that, then you can’t use the power connector plug like this.

You will have to separate the charge and discharge circuits entirely.

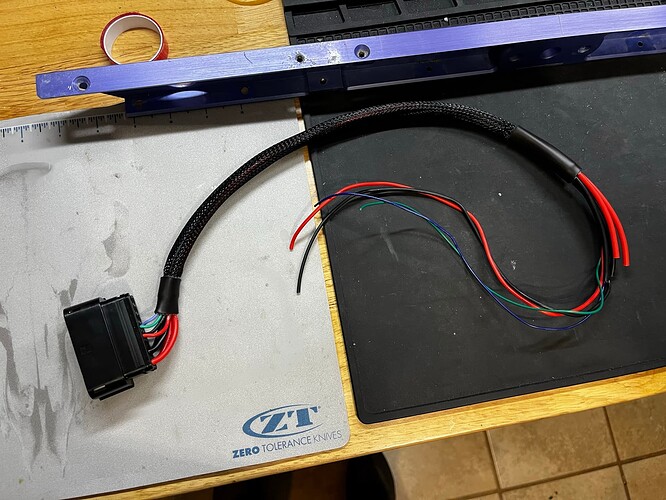

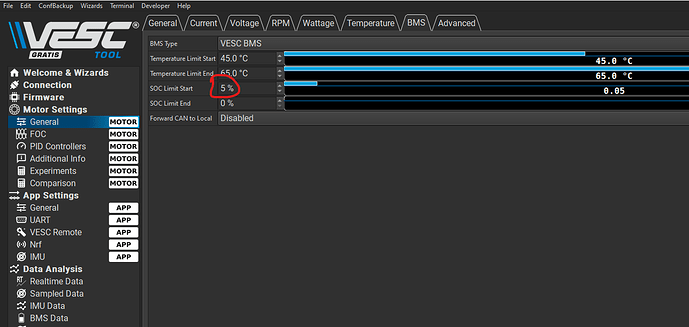

What you will see below is how I did it, and you will notice another connector next to the charge circuit. That is a 2 pin JST-PH (2.0mm pitch) connector, for using the CAN BUS connector on the ESC, for data input from the BMS I’m going to use. I will be installing the ENNOID XLITE 24S V1 BMS which you can find here:

That is a smart BMS, that connects via CAN BUS to the VESC, and so you can read BMS data through VESC tool.

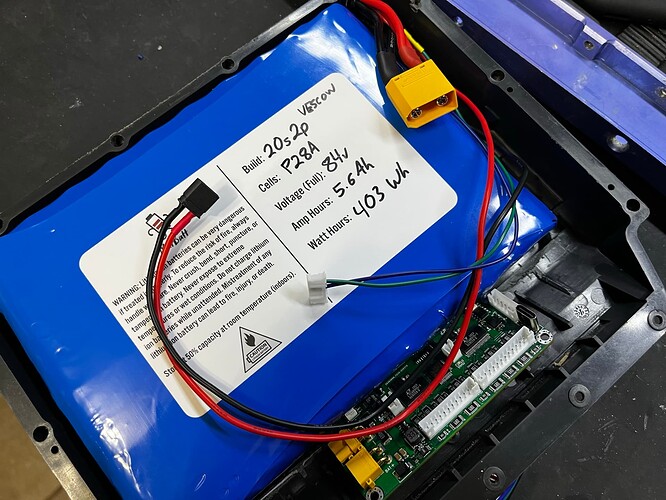

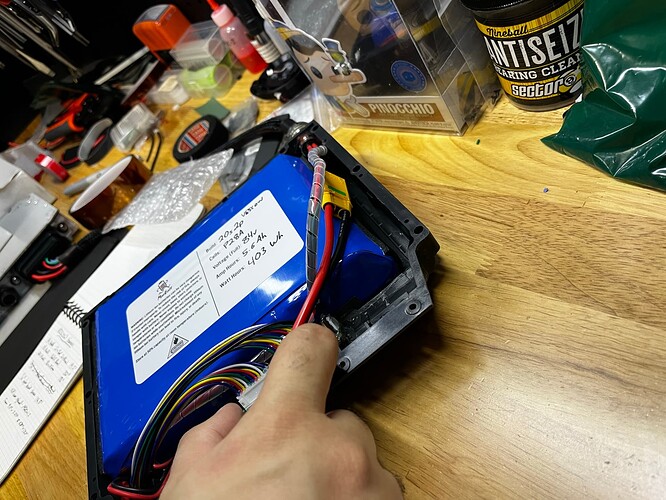

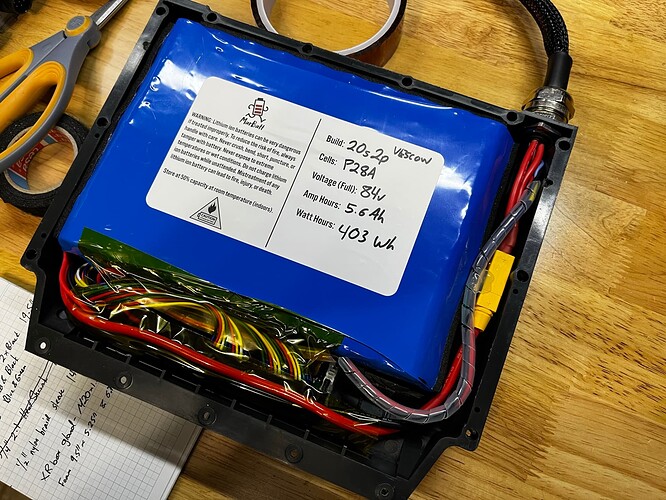

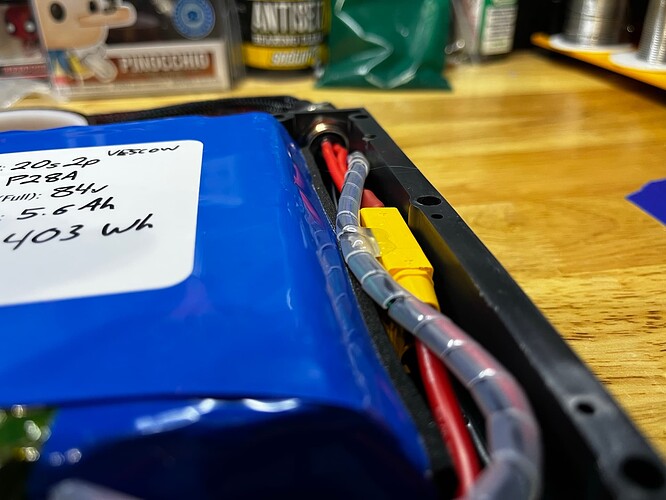

I will cover that more in detail in the next installment, focusing on the battery build and setup I do.

Apart from that, I redid the charge port connector, adding a 10 amp inline fuse on the positive wire, and segmenting it off with an XT30 connector. I also cut the excess Molex pins shorter, and added some heat shrink to them to help guard them from the other wiring in the enclosure. They are still available, and not totally cut short, in the even that I need to add other pins inside the controller box.

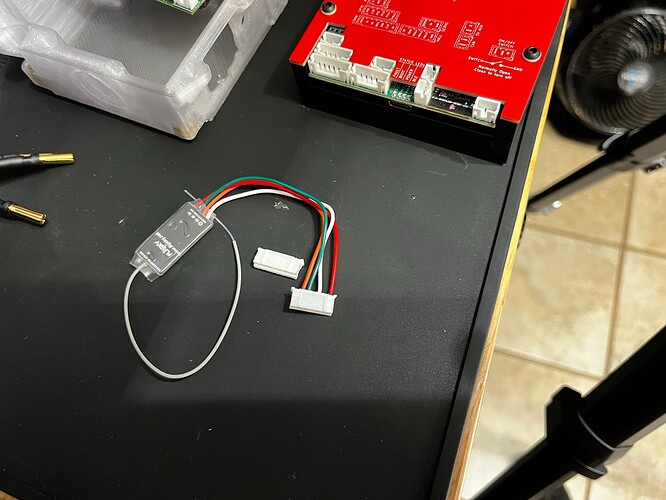

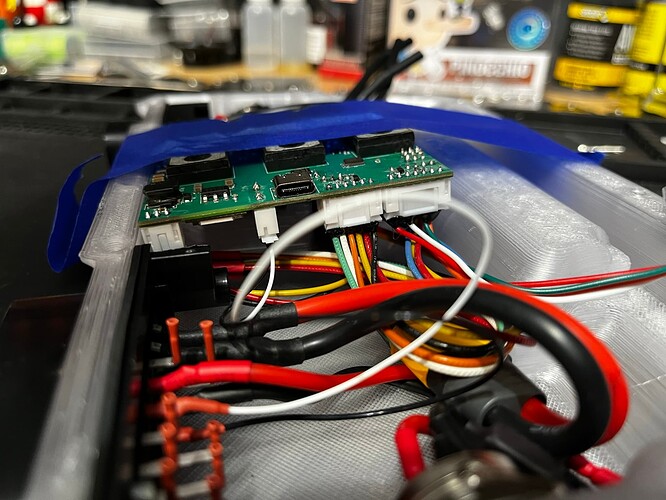

The rest of the wiring stayed the same, but I also added an external Bluetooth module. It’s a Flipsky VESC BT module that you can find here:Amazon.com

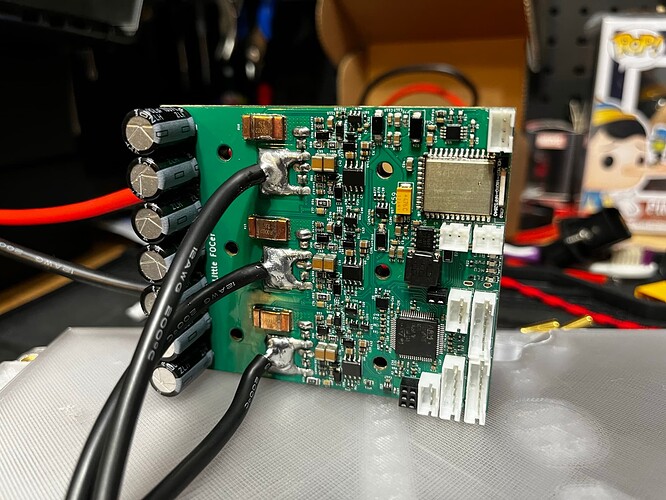

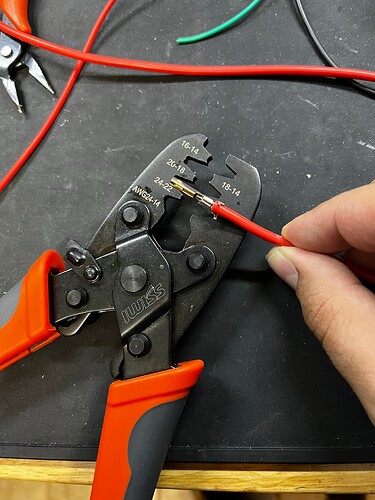

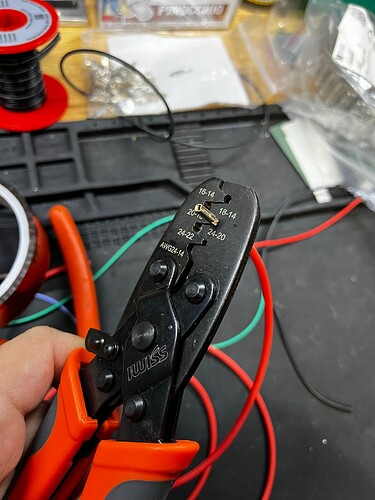

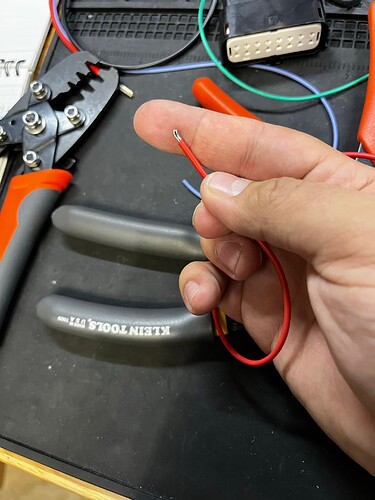

It is already programmed to work with a VESC based controller, and so you don’t have to do any software setup. The connector however, does have to be re-pinned. You can use a fine pick or tweezer to lift the wings of the JST connector, and slide the crimps out, and then replace them into an appropriate JST-PH connector following the pin out of the Little FOCer V3/V3.1.

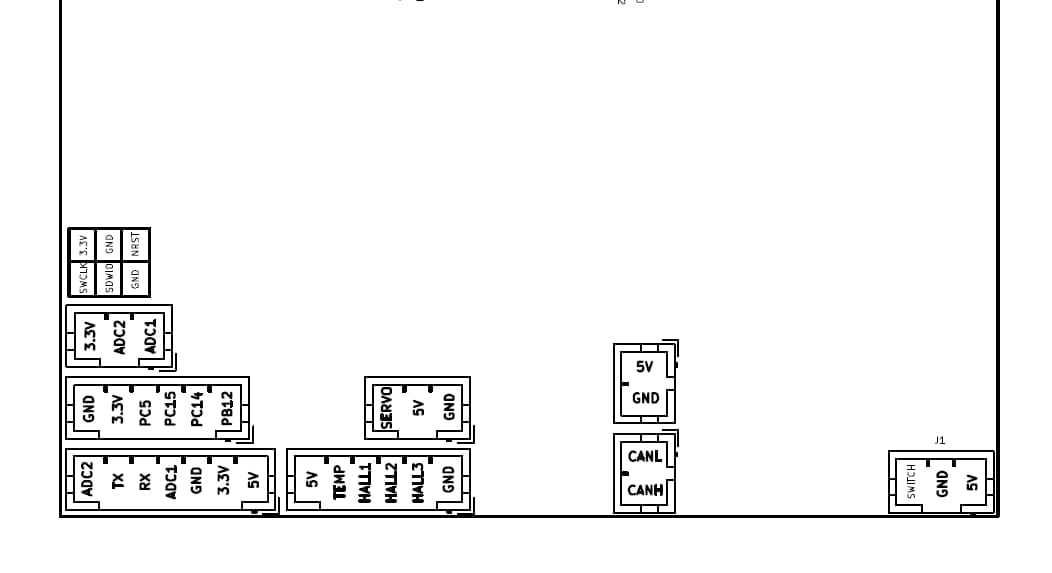

Note the required pins for the UART connection that the module uses, specifically the 5v, Ground, TX, and RX pins. They are visible on the module, and the pin out is below.

As another small modification, I added a touch of hot glue around the JST connector wires, for a bit of strain relief. I usually do this for wiring that ends up getting bent and pressed down, since it can help to relieve stress at the crimp and connection failure.

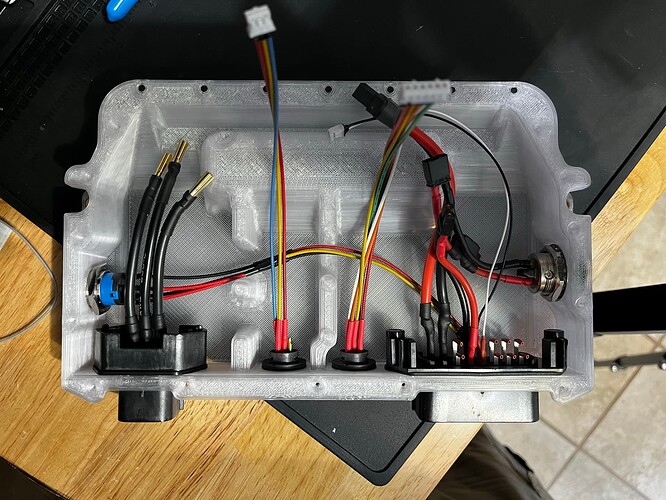

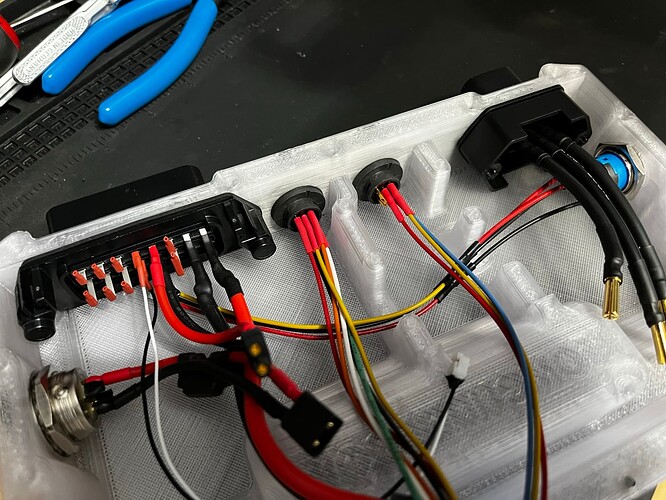

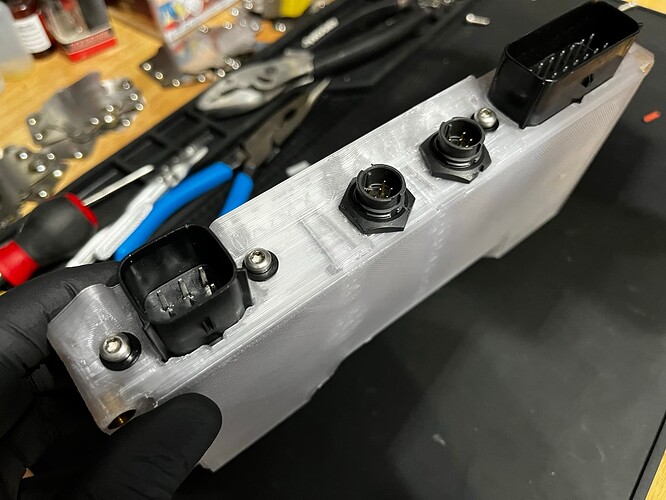

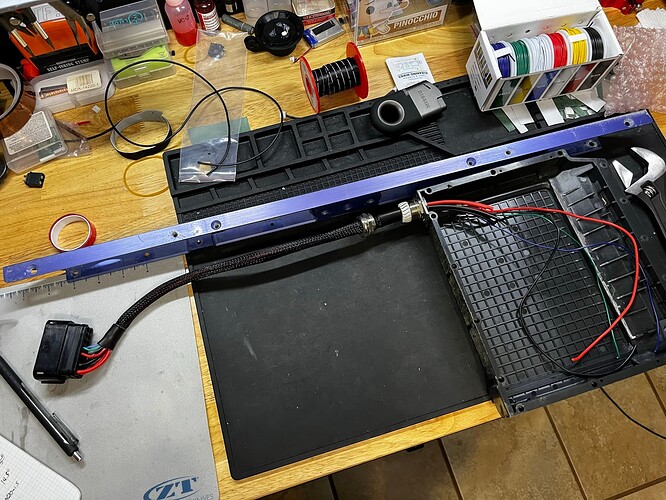

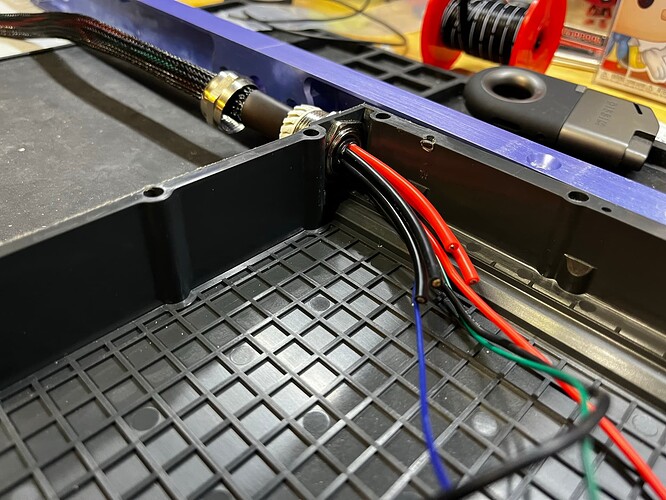

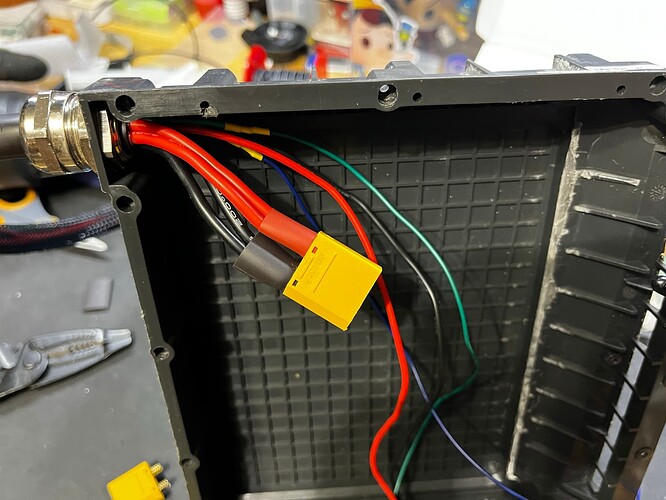

Once all that was done, I began to actually place the connectors and wiring into the box. It’s mostly straightforward, and everything goes where it fits.

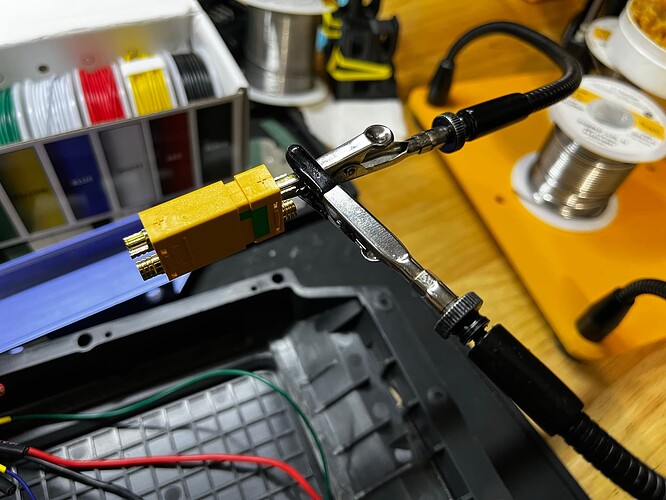

It’s important to note that when it comes to tightening down the retention rings on some of the connectors, that you may need some narrow nose pliers in order to navigate their spots.

Also, note that there are 2 Switchcraft connectors that look similar, but have different wiring.

-

The plug containing 3 wires goes to the dedicated ADC input on the left side of the pin out diagram above. This is for the foot sensor, and should be placed closer to the smaller 6-pin Molex connector for the motor.

-

The plug containing 6 wires goes to the motor sensor input next to the UART port that the Bluetooth module was plugged into. This is the port with pins marked for 5v, Temp, Hall1, Hall2, Hall3, and Ground. These are the motor sensor wires, and that plug should be placed closer to the larger 16-pin Molex for the power wiring harness.

Moving on from there, I connected the charge port to the XT30 on the Molex connector, and set about to connect everything to the Little FOCer. Please note the bullet points above, regarding pinout. Especially for the foot sensor.

Also, the kit includes some screws that work fine for the Molex connectors. I used different ones, specifically M4.5 (metric) screws for plastic that I ordered from McMaster-Carr. They have a coarser thread, but I don’t know what the benefit would be in practice. They also use a different drive, specifically Torx Plus, and I also like to get away from Phillips screws whenever I can. Note that I also used M4 sized nylon washers under the screw heads to further buffer the pressure on the 3D printed box walls.

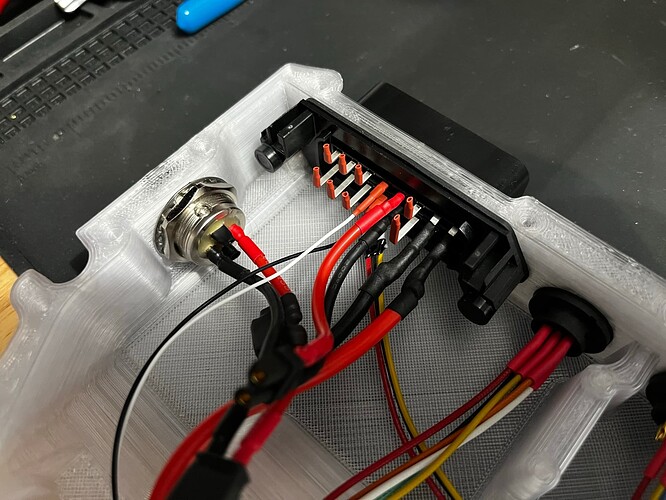

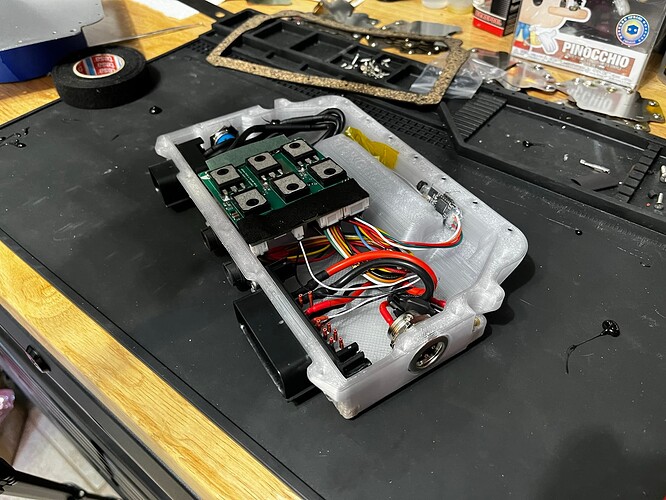

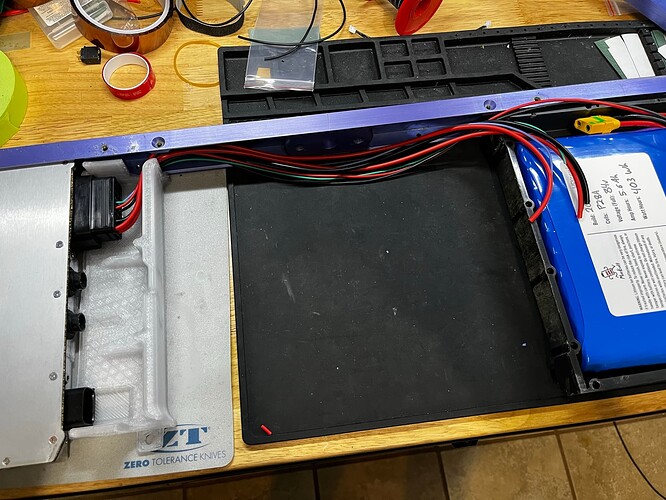

Once everything is actually in the box and secured, the rest is both simple and tricky. You do have to do a lot of very careful wire management and folding, taking care not to pinch wires or create pressure points where a sharp edge or PCB component can short out after vibrating through a wire’s insulation after a few hundred miles of riding. This is why I tend to redo wiring, as I try to anticipate compressive forces and abrasion that happens from pressure and vibration from riding. It’s an eskate thing.

Pressure + Vibration = Abrasion.

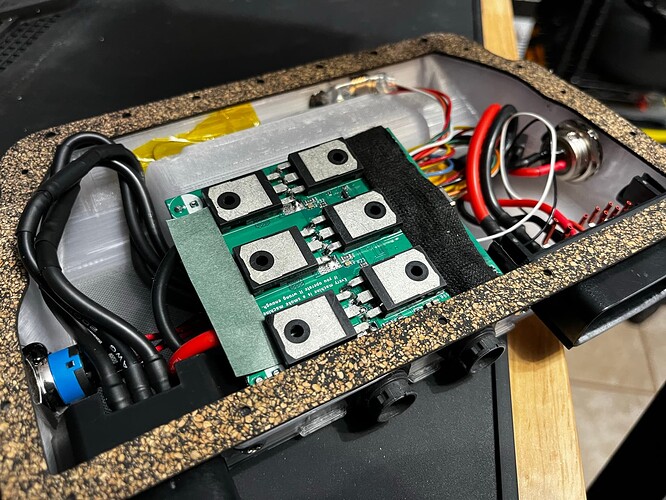

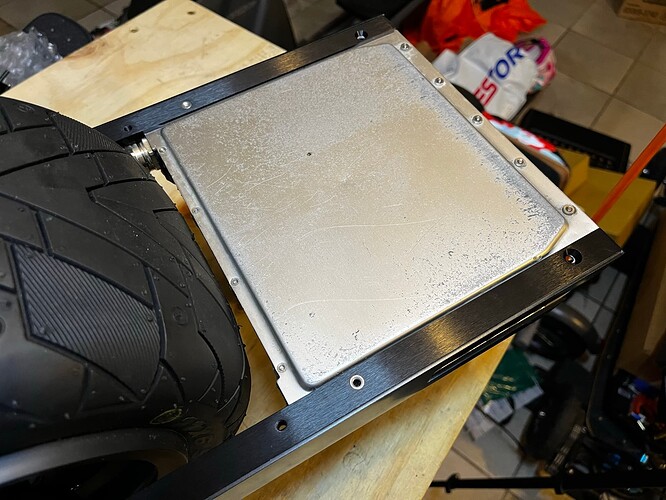

As can be seen above, I also added a strip of fish paper insulation over the solder points where the power inputs enter the PCB, and a strip of Tesa harness tape over the other end of the PCB. This is just for some extra caution, as the lid is aluminum, serving as the heat sink for the FOCer’s MOSFETs, and I don’t want to risk a large impact leading to a short against the lid.

In pressing the FOCer down onto the support posts, you should be able to feel and see if the wires are clearing, and reach in and adjust the power wires and phase wires as the FOCer is further seated.

There is a lip in the box where the PCB itself should sit, and if it sits there with some pressure, then it is probably decently cleared for the final pressure from the lid.

There is an included thermal pad in the kit, and so you can just cut that to size to lay over the MOSFETs. Make sure that you do not damage this , as these particular MOSFETs have a metal face, and they are conductive. Without insulation, those will short circuit the motor phases, and the ESC will explode.

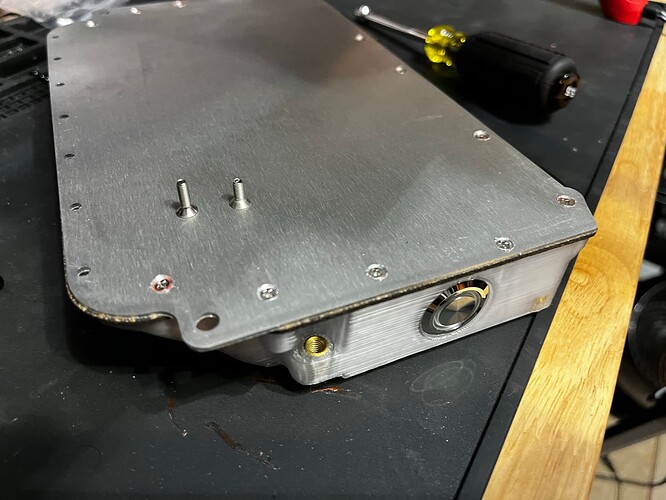

Regarding the lid, the kit did include hardware, screws, etc. As mentioned in the video, I found that the M3 countersunk screws were too long, and stood too proud of the edge of the M3 nuts on the top of the lid. Having a selection of screws, I replaced them with a size that was 2mm shorter, and they ended up pretty trued up with the edge. Again, I don’t know if that would have been a clearance issue, but I would prefer a more flush result with those screws.

The smaller screws appear to be wood screws, and they seemed to hold fine in the printed plastic box. What I did myself, was use a specific type of resin-based thread locker, Vibratite VC-3. You can find it here:

https://amzn.to/3U2DJlz

or

https://amzn.to/3LdbvAz

This stuff is a bit annoying to work with sometimes, but when you are fastening into plastic, it’s one of the few options there are. It’s a resin, and so it doesn’t “cure” like a regular Loctite would. Instead, you apply it to a screw’s threads, wait for it to dry, and it acts like a friction patch. It’s also repositionable, so you can adjust a screw and it will still hold.

As you can see in the video, mine was starting to dry up a bit. I transfered it from the brush bottle a while ago because the lid was becoming sealed shut from drying resin.

Anyway, it can help to hold a screw into a material, such as these small wood screws into the printed plastic.

For further reference, the hex size for the M3 screws is a 2mm driver, and the nuts required a 5.5mm hex socket driver.

That about concludes this installment. Thank you for reading, I hope it was helpful. The next installment will focus on the battery and wiring harness.